We turn minutes into seconds

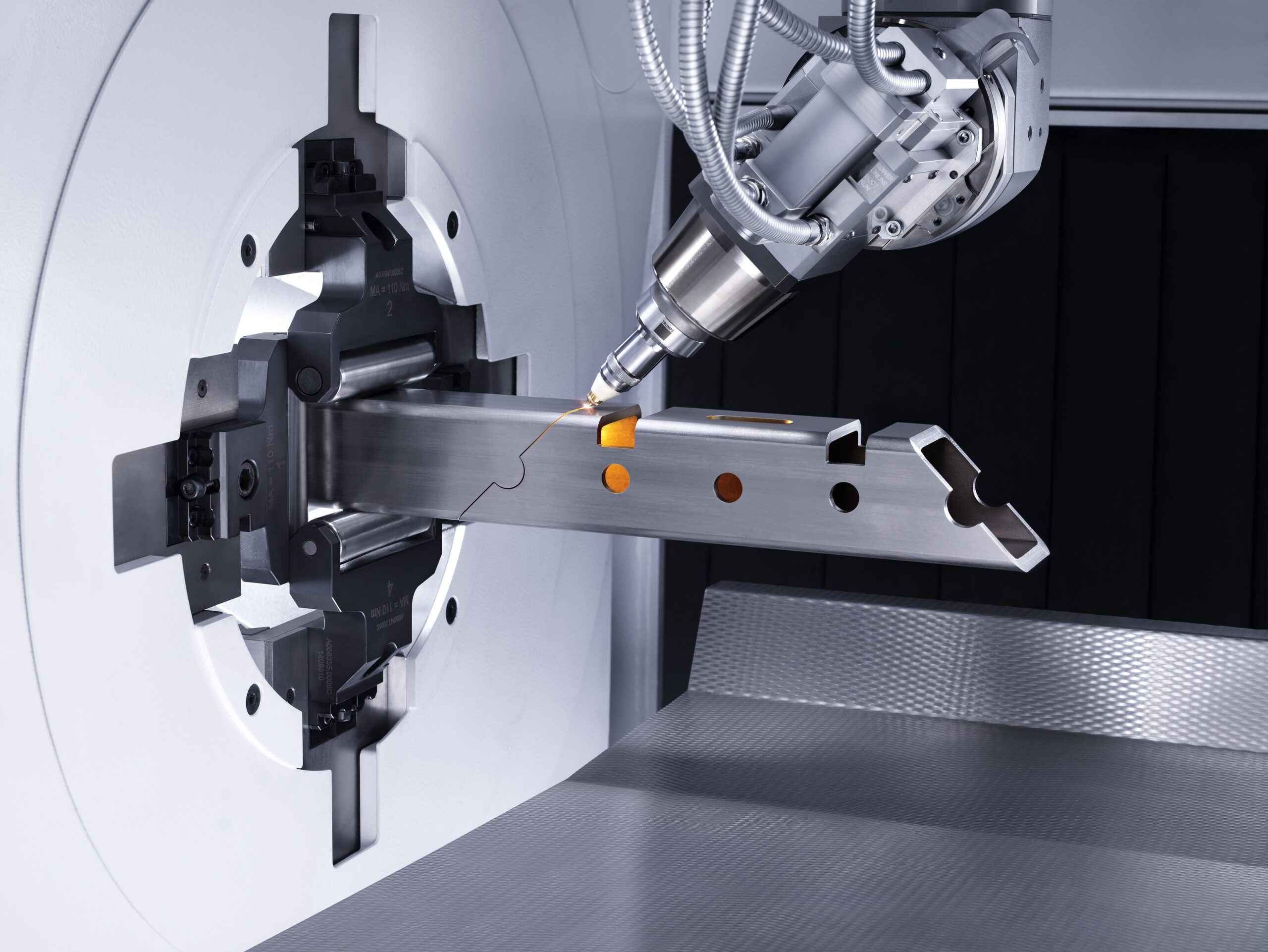

QuickTube 2D and 3D Laser Tube Cutting

NMF Industries is a specialist in both traditional tube laser cutting and advanced 3D laser tube cutting. The 3D laser tube cutting ensures a unique uniformity and precision that provides an efficient production flow in post-processing – and great savings in your own production.

A saving of up to 30% of the normal time spent on several workshop tasks – sounds too good to be true?

We are convinced that 3D laser tube cutting is the fastest way to work in steel and aluminum in the future. With the latest 3D laser cutting technology, we simultaneously eliminate several expensive operations such as drilling, sawing, milling, countersinking and punching.

We make it easy for you to deliver quality

The earlier we are involved in a project, the greater the advantage for the architects, builders and contractors benefitting from our skills and experience will be resulting in an optimal solution created in a jointly corporation.

When we supply components for larger frames and structures, we bring many years of experience with user-friendliness and efficiency into the project. We engrave ID numbers on the individual parts, making it easy for the welders to assemble them. With tapping solutions, we ensure a solid and efficient assembly of sheet metal and pipe parts, if possible aided by engraved instructions. It couldn't be easier!

A world of possibilities 2D and 3D laser tube cutting

Contact us for a tour and a demonstration of the possibilities of your project