Welding

At NMF Industries, we offer welding in aluminum, carbon steel and stainless steel. Our broad experience will help you effectively achieve your task.

Our welders are certified according to ISO 9606, and daily we work in accordance with 3834-2 (up to and incl. EXC 3), which ensures that tasks are carried out according to our quality management procedures.

We employ qualified welding coordinators, and for NDT testing (Nondestructive testing) we work closely with external companies. NDT is used to test welds for any defects that are not seen by visual inspection.

TIG-welding

We execute TIG welding in stainless steel and aluminum. Most often we supply this type of welding to industries where the finish requirements are high.

TIG (Tungsten Inactive Gas). The arc is a tungsten electrode that withstand high heat and at the same time provides a small heat zone, which is an advantage since TIG welding is usually carried out with thinner material.

MIG og MAG welding

MIG and MAG welding are efficient forms of welding, which we perform with great precision.

MIG (Inert Gas) is most often used for welding aluminum, stainless steel and other metals where the gas is inert, i.e. not part of the welding process.

MAG (Active Gas) is most often welding in steel materials with CO₂ (carbon dioxide), where the gas contributes to the melting and weld pool.

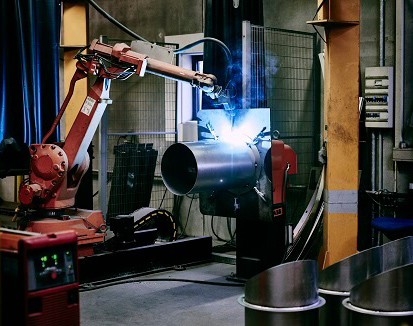

Robotwelding

Our welding robot can perform TIG/MIG/MAG and CMT welding. CMT welder makes it possible to weld in thinner metals.

It handles a workpiece weight of max. 1,100 kg.

Robotic welding increases the productivity for larger series.