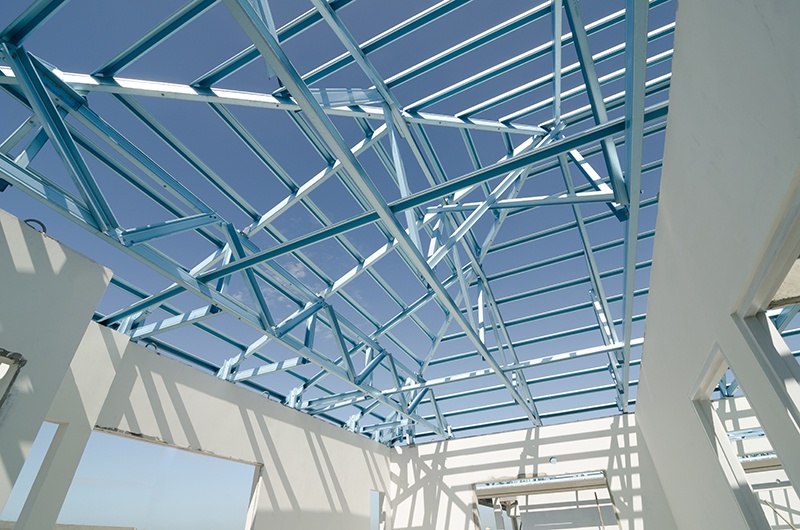

When it comes to merging form and function in new constructions, steel or aluminium are often obvious choices of materials. Whether your project needs a load-bearing structure or a unique feature to complete the overall impression, QuickTube and the Skovsager Group are ready to provide expert advice and the latest technology on the market.

Our latest investment in northern Europe’s largest profile and laser tube cutter means we can offer our customers completely new possibilities in laser tube cutting and creative construction, making the existing limits on dimensions a thing of the past. The possibilities are almost endless, and there’s no need to compromise on project budgets – in fact, quite the contrary. In our experience, the earlier we’re involved in a project, the more architects, developers and contractors can reap the benefits of our skills and experience with 3D laser cutting.

QuickTube can cut the large workpieces for your project at our own factory and then ship them to the construction site, where the tailor-made elements can be readily assembled according to your specific requirements. This saves you valuable time on having to adapt tubes and profiles onsite.

Our new laser cutter is a fibre laser cutting machine, so it is also suitable for cutting copper and brass. With the array of machinery now at our disposal, the possibilities are virtually infinite. We’re always ready to invest both time and technology if your project requires it. So don’t hesitate to contact Factory Manager Henrik Bøgh (QuickTube) on tel. +45 2272 3366 or Technical Sales Manager Kim Faarup (Skovsager Group) on tel. +45 4098 0916 for an informal chat about the potential for your next project.